Introduction:

When an indispensable piece of equipment abruptly stops functioning in the middle of a task, most people scratch their heads, trying to figure out what could be wrong, although it could be any number of things. This is a terrible situation that most individuals have probably encountered.

By reading this comprehensive guide to heavy equipment troubleshooting, you can be fully aware of the problem and the appropriate course of action. Everything you require to accurately identify and fix common issues and preserve the effectiveness of your operations is available right here.

Common Problems with Heavy Machinery:

Engine Failures

Problems with Heavy machine tools and engines are among the most frequent ones. If this issue arises, you should anticipate a considerable delay in your project's completion date. Symptoms can include anything from strange noises and smoke to a total loss of electricity.

A number of factors, such as contaminated gasoline, poor lubrication, and the ageing process of engine parts over time, can cause engine issues. Fuel contamination can result in clogged injectors and filters, which can lower engine performance and even cause total failures. By keeping a regular eye on engine oil levels and fuel quality, one can save costly repairs and needless downtime.

Hydraulic System Failures

Another frequent issue that can arise with your gear is a malfunctioning hydraulic system. If you observe leaks, a drop in pressure, or broken parts, these are classic signs of a hydraulic breakdown. This could not only stop your operations but also endanger the operator's safety.

Two common sources of problems with hydraulic systems are air entrapment and contaminated fluid. These may cause hydraulic parts to deteriorate and work less well. These issues can be avoided by adhering to fluid management procedures and performing routine wear and leak inspections.

Electrical Problems

Electrical problems with construction equipment can be especially difficult to diagnose because of their complexity. Electrical malfunctions in construction equipment, such as short circuits, dead batteries, or malfunctioning sensors, can stop activities. To avoid prolonged downtime, these problems must be expertly diagnosed.

Your electrical problems could be caused by anything from rusted connections to broken control devices. Routine corrosion inspections, proper wiring routing, and insulation can prevent unexpected electrical failures.

Structural and Mechanical Wear:

Components such as bearings, gears, and structural frames are vulnerable to constant stress and deterioration, especially with extensive usage. Maintaining equipment integrity necessitates routine checks for wear indicators and quick action on any damage.

Diagnostics Equipment and Tools

The secret to identifying various issues with your equipment is having a collection of diagnostic tools and equipment. Listed below are a few tools advisable to be kept handy:

- Multimeters

Flexible instruments that are used to measure resistance, voltage, and current in electrical systems. They function by transforming the electrical input into a number that appears on the screen.

- Pressure Gauges

These are mechanical components that move in reaction to changes in pressure to measure the pressure exerted inside a system, usually liquids or gases, and show the value on a dial or digital screen.

- Advanced Diagnostic Software

These instruments offer a more profound understanding of the system's condition, decipher error codes, and track performance indicators to anticipate possible malfunctions.

- Thermal Imaging Cameras

They detect temperature abnormalities and precisely target locations that require further investigation to find electrical defects and overheating components.

- Vibration Analysis Equipment

These instruments examine vibration patterns to pinpoint underlying mechanical problems, making them crucial for identifying imbalances and bearing failures.

Preventive Maintenance Techniques for Large Equipment

Routine Inspections and Predictive Maintenance

Routine inspections are the secret to spotting minor problems before they get worse. Integrating predictive maintenance technologies like fleet maintenance software can help improve the process if you manage a sizable fleet of vehicles. This proactive approach allows repairs and changes to be made on time, taking into account the real state of the machinery.

Customized Maintenance Plans

Prevention is simpler than treatment. Creating a preventative maintenance schedule is the best approach to preventing failure, avoiding troubleshooting entirely, and maximizing equipment longevity.

By customizing your schedules to meet the specific requirements of every machine, taking into account operational usage and manufacturer recommendations, you can ensure efficiency and avoid unanticipated breakdowns. This individualized method ensures that all facets of the equipment are maintained by covering structural, mechanical, and electrical components.

Documentation and Ongoing Improvement

Thorough records of all maintenance operations, examinations, and repairs are essential to creating a historical performance profile for every piece of machinery. This documentation assists in identifying trends or reoccurring problems and makes it possible to build future maintenance strategies based on real-world information and operational input.

Maintaining proper documentation might also help you comply with OSHA laws. Having a large collection of paper or digital records is a terrific advantage if you want to avoid trouble with the law.

Educating and Providing Support to Maintenance Teams

A maintenance program is only as effective as the people who execute it. Teams can be empowered by receiving thorough training on specialized equipment as well as general maintenance and safety procedures. Promoting decision-making based on the results of inspections guarantees the timely and effective completion of maintenance work.

This simplified method maximizes your return on investment by extending the equipment's lifespan, avoiding expensive repairs, and improving the dependability and efficiency of your heavy machinery.

Techniques for Troubleshooting

- Predictive maintenance: Using analytics to predict possible breakdowns, maintenance can be planned for the best possible times.

- Component Isolation: By methodically examining separate pieces of equipment, the exact source of an issue can be pinpointed, and precise, cost-effective repairs can be made.

- Simulation and Modelling: Software for simulation and modelling can replicate failure situations for complicated problems, assisting technicians in creating exact solutions.

- Safety considerations: Using analytics to predict possible breakdowns, maintenance can be planned for the best possible times.

- Predictive maintenance: Using analytics to predict possible breakdowns, maintenance can be planned for the best possible times.

- Predictive maintenance: When troubleshooting heavy machinery, safety should always come first. It is imperative to comprehend potential risks and wear protective equipment (PPE) such as boots, gloves, and glasses.

Safety considerations: When troubleshooting heavy machinery, safety should always come first. It is imperative to comprehend potential risks and wear protective equipment (PPE) such as boots, gloves, and glasses.

- Safety considerations: When troubleshooting heavy machinery, safety should always come first. It is imperative to comprehend potential risks and wear protective equipment (PPE) such as boots, gloves, and glasses.

- Training and Skill Development: Staying updated with heavy machine technology requires ongoing training and skill development. Encouraging your staff to earn certificates can improve their knowledge and abilities in troubleshooting.

Bring in the Experts: Occasionally, a task is too large or intricate for you to handle alone. At such a point, you should call qualified equipment mechanics to receive their assistance.

Conclusion

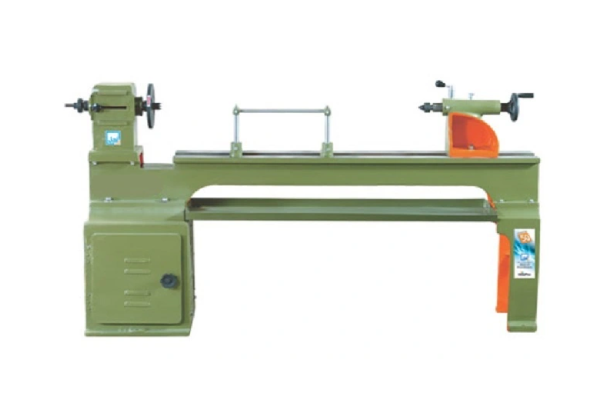

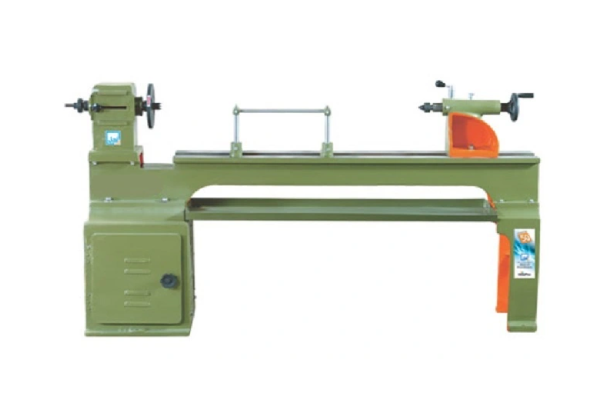

Heavy machine tool troubleshooting often calls for a combination of technical knowledge, systematic diagnostics, and proactive upkeep. These are the best defense against heavy equipment failure. They are a calculated investment in the durability and dependability of your equipment, not just boxes to check every so often.

Organizations may drastically lower the frequency of unplanned equipment breakdowns by customizing maintenance schedules, conducting regular inspections, utilizing predictive maintenance technology, keeping thorough records, and providing competent maintenance personnel with the necessary authority.

In the end, this proactive strategy strengthens the bottom line by improving operational efficiency and safety as well as helping to create a more predictable and controllable operational cost structure.

Shital Machines is a leading heavy machine tool manufacturer in Rajkot, India. It is dedicated to providing top-notch machinery supported by trustworthy after-sale services. Put your trust in Shital Machines for all your heavy machinery requirements, and you will receive unmatched performance and dependability in every task.