Contact Our Team

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

CALL US: + (91)-8879987584

MAIL US: [email protected]

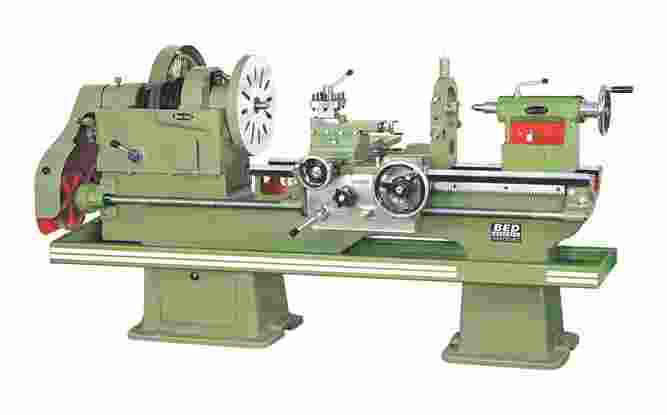

Heavy Duty Lathe (MAX)

Standard Accessories :

- Chuck Plate

- Gear Set

- Centre Adaptor

- Dead Centres

- Dial Indicator

- Square Tool Post

- Tool Post Key

Optional Accessories :

- Steady Rest

- Follow Rest

- Rear Tool Post

- Norton Gear Box

- Machine Lamp

- Face Plate

- Electrical Fitting

- True Chuck & Dog Chuck

- Key Way Milling Attachment

- Tool Post Grinder

- Quick Change Tool Post

- Turning Attachment

- Coolant Pump with Tank & Fittings

- High Tensile Casting

- Latest Design Head Stock

- Hardened & Ground Bed & Spindle

Shital Machines: Heavy Duty Lathe Machine Manufacturer in Rajkot & India

Shital Machine Tools is one of India's leading heavy duty lathe machine manufacturers in Rajkot & India, designing and engineering complex machinery to handle larger weights. As a result, these machines are built with strong machining capabilities that enable them with turning huge metalwork parts.

These heavy-duty lathe machines with specialised features such as sturdy one-piece planar lathe beds and ground headstock spindles give a sturdy platform while also enabling smooth parallel movement of the carriage and tailstock in line with the spindle's axis. Shital Machines Lathe uses alloy steel to give the machine longevity throughout time by giving it strength and sturdiness. In order to increase the power of the rotating spindles and bearings, a specialised oil pump is used in the machines to reduce internal tensions and friction in the lathe mechanism and help to cool sections that have become overheated. Moreover, Shital Machine Tools, being the finest heavy duty lathe machine manufacturers in Rajkot, has added bayonet-type spindle nose fittings to guarantee an excellent fastening mechanism, improved safety, reduced likelihood of an accident, and facilitate easy part replacement.

Features of Heavy Duty Lathe Machine

A heavy-duty lathe machine is an extraordinary industrial machine with various characteristics and uses. Listed below are the prominent features of heavy-duty lathe machines:

- Head Stock

- The flat seat is perfectly matched by precision hand-scraping

- The spindle is made from high carbon steel, which rotates on five no. of bearings for smooth running

- Heavy-grade thrust bearings provide the spindle with perfect balance and thrust

- In addition, Taper Roller Bearings are used in the headstock

- Carriage

- Sturdy design with long, carefully scraped sliding surfaces

- For taper turning, a swivelling compound slide has precise indexing

- A four-way steel turret tool post

- The Apron

- Double wall design with automatic interlock

- Gears and bearings, including worm, have suitable oiling arrangement

- Prevent simultaneous engagement of feed shaft and lead screw in Lathe machine

- Tail Stock

- Strong & rigid construction

- The quill is relatively thick and properly graduated

- Provided with a set-over motion for taper turning

- Lead-Screw

- Inch calibrated

- Large diameter

- Made of highly resistant alloy steel

- Threads are exceptionally precisely machined in a lathe machine

Contact Us

Shital Machine Tools is committed to producing top-notch lathe machines. For over 36 years, the Company has successfully provided dependable, effective lathe machines to various industries, including auto garages, multipurpose industrial facilities, automotive, fabrication, metalworking shops, and other sectors. With a wealth of knowledge in Engineering Workshop Tools, Machinery, and Accessories, the Company has made a name for itself. Shital Machines is associated with offering integrity and transparency to offer quality supplements.

Thanks to the innovative work of our skilled staff and committed team, we are now regarded as one of the most reliable producers and suppliers of lathe machines in the entire globe. Light-duty lathe machines, medium-duty lathe machines, heavy duty lathe machines, and extra heavy duty lathe machines are among our premium product offerings.

Don't hesitate to contact us to learn more about the cost of a heavy-duty lathe machine since we have a large selection of machine models with varying features, sizes, specs, and attachments.

FAQ's (Frequently Asked questions)

There are multiple versions of the Heavy-Duty Lathe Machine model available. The machine has a highly accurate and powerful motor. It works well in many different sectors. Metals, as well as other materials, can be processed using it. It operates with great flexibility and precision.

The engine lathe is the most often used lathe machine type. It is well known for its adaptability and is a mainstay in machine shops since it can handle various turning tasks. Engine lathes are useful for jobs ranging from basic cutting to intricate shaping, and they can deal with multiple materials.

The metal cutting lathes can be classified into various types based on their industrial history and unique shop applications. These include centre lathes or engine lathes, speed lathes or inverter lathes, capstan lathes or turret lathes, tool room lathes, bench lathes, automatic lathes, oilfield or oil country lathes with large spindle bores and double chuck system, horizontal lathes or vertical lathes, conventional lathes, manual and CNC lathes.

The four main types of Lathes are listed below:

- Speed Lathe

- Engine Lathe

- Turret Lathes

- CNC Lathes