Introduction:

Air Compressor machine is a crucial power source widely used in many industrial areas. It has distinguished itself from alternative power sources with its safety, adaptability, and convenience. Compressed air provides a consistently uniform force and guarantees smooth transitions. When compared to other power sources, it also offers an enhanced power-to-weight ratio and can achieve higher pressures with fewer air volumes.

The use of air machinery can result in efficient installation procedures, decreased downtime, and lower maintenance expenses due to the use of fewer components.

Chemicals, food and beverage goods, medicines, nuclear power, and many other industries all require air compressors in their production processes. The advancement of air compressor technology has brought about a revolution in these industries by enhancing their speed, safety, and efficiency.

Nevertheless, different industries utilize different types of air compressors. Every industry has different needs and requirements, demanding air compressor manufacturers to meet their unique requirements. Read along to get complete details about the air compressor.

Types of Air Compressors:

The most popular type of air compressor machine has pressure produced through positive displacement mechanisms. Reciprocating compressors, rotary screw compressors and centrifugal compressors are the most commonly used types of air compressors. Let's look into each of the major types in more detail:

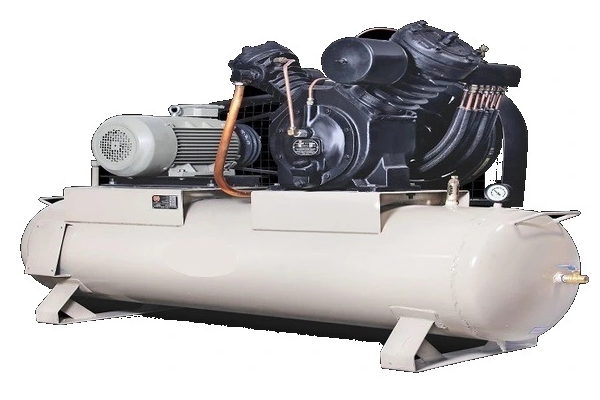

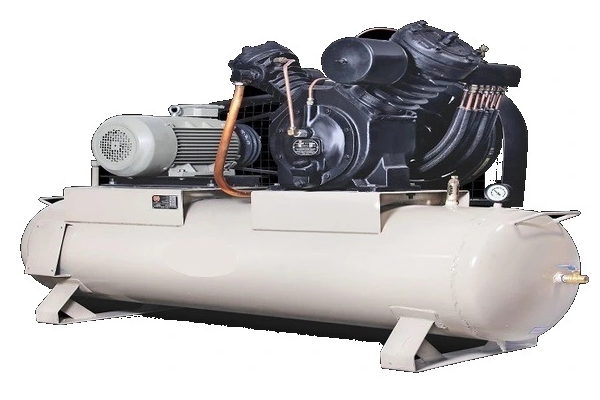

- Reciprocating Compressors:

A reciprocating compressor, also known as a piston compressor, is a positive displacement compressor that delivers gases at high pressure using pistons powered by a crankshaft. Multistage reciprocating compressors may generate pressures as high as 5,000 PSIG.

The reciprocating compressor is the vital and most expensive system in the facility, so it requires complete attention. This type of machinery is important for many different businesses, including refineries, petrochemical plants, and gas transmission pipes.

- Rotary Screw Compressors:

A rotary-type positive-displacement mechanism is used by rotary-screw compressors, which include air compressors. Commonly used in industrial settings, these compressors take the place of more conventional piston compressors in situations requiring higher volumes of compressed gas, such as in large refrigeration cycles like chillers or compressed air systems that power air-driven tools like impact wrenches and jackhammers. Because the intrinsic leakage in the rotors increases significantly with lower rotor sizes, this kind of mechanism is less appropriate for smaller compressors than piston compressors.

Unlike reciprocating compressors, screw compressors do not have a maximum pressure of 215 PSI and are not designed with high-pressure requirements in mind. Rust can build up in rotating screw compressors. Therefore, it's best to avoid leaving them inactive for long duration.

- Centrifugal Compressors:

A type of dynamic compressor that increases a gas's pressure and converts kinetic energy into potential energy is a Centrifugal Compressor. Its main purpose is to move gas, and it is commonly used to compress gases (air, natural gas, and refrigerants) in various industrial applications.

Important Things to Think About:

In addition to air demand and application, the following additional considerations affect your decision:

- Power Source:

Electric air compressors are less maintenance-intensive and quieter, but their CFM output may be constrained. Although they must be ventilated and have a larger CFM, gas-powered compressors are noisier.

- Tank Capacity:

The compressed air stored in the air tank enables continuous tool use without the need for frequent compressor cycles. More capacity (about 6–10 gallons for most workshops) guarantees more efficient operation.

- Noise Level

For situations where noise is a concern, look for an electric compressor with quieter operation or one with noise-reduction features.

- Portability

A model on wheels is perfect if you need to move your air compressor around the workshop.

How to Choose the Right Air Compressor

You can select an air compressor that fulfils your requirements, delivers peak performance, and ensures long-term dependability by carefully considering several criteria and their alignment with your application. Here is a list of things to think about:

- Operating pressure requirement: Find out the highest pressure required in your application. Think about the PSI needs of the instruments or apparatus you plan to employ in combination with the compressor.

- Duty cycle: Find out how long your application is scheduled to run. While some machinery must run constantly, others have irregular utilization patterns. Select a compressor that can efficiently manage the duty cycle.

- Maintenance requirements:Assess the compressor's maintenance requirements. Take into account things like routine maintenance, filter replacements, and oil changes. Check to see if the maintenance plan fits your available time and resources.

- Type of compressor: Select from various compressors, including rotary screw, rotary vane, and reciprocating (piston), depending on your needs and air compressor machine price.

- Extra features:Take into account additional features that improve performance and usability. These could include automated start/stop, digital controls, integrated air filtration systems, thermal overload safety, pressure regulators, and built-in air dryers.

- Safety aspects to consider: Give top priority to safety elements, including pressure release valves, appropriate grounding, and compliance with safety regulations.

- Future growth: Take into account any prospective increases or modifications to your air demand. If growth is estimated, be sure the compressor can handle the increasing demand.

Conclusion

Choosing a suitable air compressor allows you to work swiftly and effectively on various workshop jobs. If you look into the various air compressor options and assess your air demand and workshop limits, you will be well-equipped to make an informed choice. Before buying an air compressor, consider factors such as the type of compressor, performance metrics, maintenance requirements, and cost considerations.

A wide variety of air compressors designed to satisfy different purposes are available from Shital Machines, a trusted air compressor machine manufacturer in Rajkot and India. You can be rest assured of finding the best quality machinery when it comes to reliability and quality. Check out our range of air compressors, and don't hesitate to contact us for more information or a free quote at any time.