What is Drill Machine?

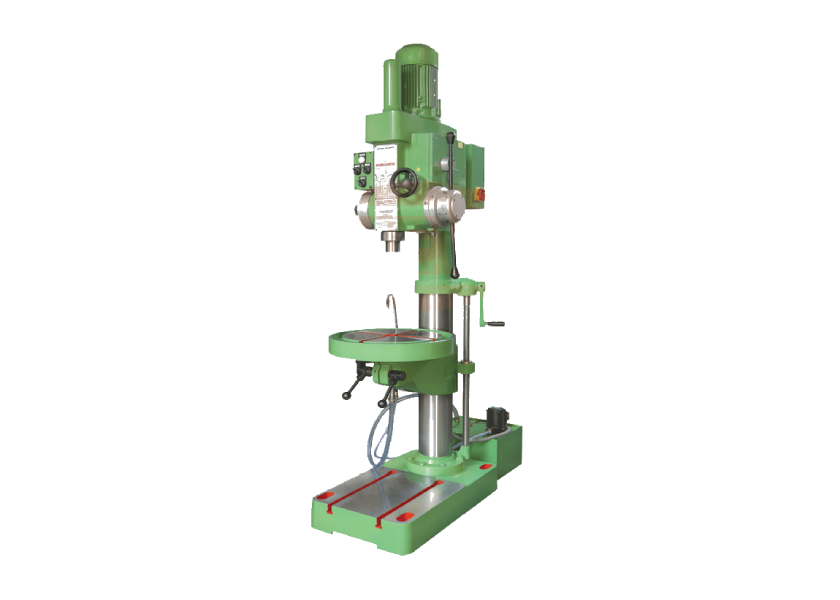

A pillar drill machine, also known as a drill press, is a powerful tool for drilling precise holes in various materials. It's a strong vertical column with a spinning spindle that holds various drill bits. This machine is commonly used in workshops, factories, and construction sites. It is known for its ability to drill holes accurately and quickly.

As a prominent drill machine manufacturer in Rajkot, India, Shital Machines specialises in producing high-quality pillar drill machines. Our pillar drill machines are reliable and durable, perfect for many drilling tasks.

Features of Pillar Drill Machine

Discover the exceptional features of our Pillar Drill Machines. It is engineered to meet your drilling needs with precision and reliability. As a trusted drill machine manufacturer in Rajkot, India, we prioritise quality and performance in every aspect of our machines. Here are some of the main features of the pillar drill machine:

- Utilised to bore holes in various industrial materials

- Offers regular boring

- A robust and dependable tool

- Cost-effective in comparison to other boring tools

- Precision in creating a hole

- The quality of the machine's components is not compromised

- Offers superior machining performance with minimal or no maintenance requirements.

- Produces less vibration and noise

- Parts Balanced Correctly

- Main gear and pulley assembly beforehand

- Parts completed on an imported grinding machine

Types of Pillar Drill Machine

- Pillar Drill Machine: Our Pillar Drilling Machine offers high precision and hole-making capacities. It has a smooth surface and includes an arm, a working part, and gears made with advanced grinding machines. Being the leading drill machine manufacturer in India, we provide a selection of models that meet different needs and uses.

- All Geared Pillar Drill Machine: These drill machines are efficient and reliable, ideal for factory drilling tasks. These machines are designed to guarantee error-free drilling, meeting all production needs. They require minimal maintenance while offering superior quality.

- High Precision Pillar Drill Machine: Our High-Precision Pillar Drill Machine offers various types of pillar awls for accurate drilling. These tools, made from alloy steel, are ideal for creating precise holes in sheet metal and solid materials. They excel at fastening holes, ensuring accuracy and reliability in their use.

- Pillar Drilling Machine 38mm: Our Pillar Drilling Machine is tailored for precision drilling tasks. It offers reliable performance and durability, making it suitable for various workshops and industrial applications. It is available in different pillar diameters to accommodate diverse needs.

- Pillar Drill Machine 40mm: Pillar drill machines are used in factories due to their efficiency in drilling operations. They offer superior quality and flexibility. With easy and flexible operational methods, these machines ensure hassle-free drilling tasks.

- Pillar Drill Machine 25mm: This machine offers efficient and durable performance. Suitable for various industries, it ensures precise drilling of different items. The machine provides easy and safe operation. Additionally, our machines are reasonably priced for affordability.

Trust our drill machines for superior performance and durability, backed by our expertise as a reputable drill machine manufacturer in Rajkot, India.

Contact Us

Looking for top-quality drill machines anywhere in India? Look no further! Shital Machine Tools, your trusted drill machine manufacturer in Rajkot & India, offers a wide range of reliable solutions, including pillar drills and tapping machines. With our commitment to excellence, we provide the best-in-class equipment tailored to your needs. Contact us today for inquiries, quotes, or assistance with all your drilling requirements. Explore our website to discover the best that Shital Machines has to offer.

FAQ's (Frequently Asked questions)

Drill machines are manufactured through a process involving design, material selection, machining, assembly, testing, packaging, and distribution.

In India, drills come in various types catering to different needs. Some common types include hand drills, cordless drills, impact drills, hammer drills, and rotary drills. Each type offers unique features and functionalities suited for specific tasks and applications.

The four types of drilling machines are radial, deep hole, automatic, and multiple spindle drilling machines.